Quality Assurance

Fusible plugs are very niche products with very segmented applications. There is no universally recognized international standard dedicated exclusively to fusible plugs. We can only find a few discrete sentences from some industrial standards where fusible plugs are included, e.g. refrigeration (UL207-2004), compressed air cylinder (ISO3807-2), steam boilers and compressed air applications (BS 1123:2006).

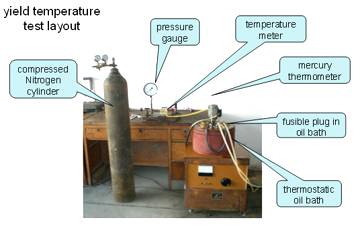

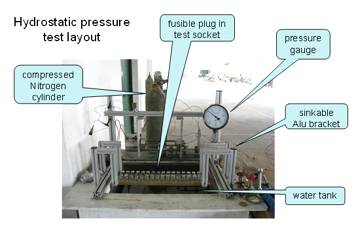

These standards specify two common types of tests in common regarding fusible plugs: the yield temperature test and the hydrostatic test. Yield temperature test is to verify that the fusible plugs operate at their designated temperature. Hydrostatic test tells whether the fusible plugs can continuously withstand normal operating pressure without leakage.

We have necessary test devices in house to check every aspect of the performance of our fusible plug. Our test results are often more reliable than third-party certificates. You can rest assured with the quality of every single product we deliver. Other types of test (including RoHS) certificates can be arranged upon agreement.

Application Note #

- We make sure that all our products function as they are designed to be. However it is the customer’s responsibility to choose fusible plugs with the right temperature rating for their application.

- Apply anaerobic sealing adhesive or thread sealing tape for installation to avoid leakage.

- Please inform us if the service pressure of your application is higher than 5.0 Mpa.

- Fusible plug does not protect against over-pressure from improper charging practices. In other words, fusible plugs only respond to over-temperature instead of over-pressure.

- Please replace the fusible plugs if you know that they have been exposed to over-temperature within 10°C of their nominal yield temperature, even if no leakage is currently observed.